WMO Burner Raffle

Our first raffle of the year will be drawn February 28th and the topic will be Waste Motor Oil (WMO). So please send in pictures of centrifuges cleaning motor oil, filters, pumping systems, vehicles and furnaces whatever you have. Essays can also qualify for the Guest blog. All pictures must include some words describing the pictures. Grand prize will be a $600 HD Oil Transfer pump.. I will dream up some other prizes too if we get a good response. I will get up a page to show off all the entries and will send the link you before the raffle is over.

Get your ticket:

Pictures with description- 1 Ticket

Videos – 5 Tickets

Essays and designs – 10 tickets.

Send entries to support@wvodesigns.com

——————————————-

Below are the entries. Lots of great stuff down there! – Leon

——————————————-

I’ve been processing WMO since day one. I’ve never processed anything else (WVO was just too hard to find and all the sources were already spoken for). My setup includes some safety devices for processing. I’ve been processing WMO for 3 years with my primary mix being 70/30 (70% WMO and 30% D2). I run it in all my vehicles (all of which are diesel including my bobcat) year round here in mid Florida. I have 2 VW Jetta TDI’s (2000 and 2001), a 1996 Mercedes E300D, 1999 F250 Superduty Crew Cab 4×4 (customized setup with a 1990 7.3 IDI motor with Banks Turbo), and a 2000 Excursion with a Powerstroke 7.3 (my wife’s “bus”). My 1999 F250 Superduty Crew with the IDI setup can run straight WMO after I process it through WVO Designs Centrifuge but I run the 70/30 mix for convenience. My Jetta’s can run WMO at 98.5% and 1.5% Pure Gum Turpentine (to boost the cetane for starting and burning) but I stick with my 70/30 mix to keep it uniform. The Mercedes and The Excursion both prefer the 70/30 mix and get the best performance and economy at that ratio…. ( Read More) – Kevin

I’ve been processing WMO since day one. I’ve never processed anything else (WVO was just too hard to find and all the sources were already spoken for). My setup includes some safety devices for processing. I’ve been processing WMO for 3 years with my primary mix being 70/30 (70% WMO and 30% D2). I run it in all my vehicles (all of which are diesel including my bobcat) year round here in mid Florida. I have 2 VW Jetta TDI’s (2000 and 2001), a 1996 Mercedes E300D, 1999 F250 Superduty Crew Cab 4×4 (customized setup with a 1990 7.3 IDI motor with Banks Turbo), and a 2000 Excursion with a Powerstroke 7.3 (my wife’s “bus”). My 1999 F250 Superduty Crew with the IDI setup can run straight WMO after I process it through WVO Designs Centrifuge but I run the 70/30 mix for convenience. My Jetta’s can run WMO at 98.5% and 1.5% Pure Gum Turpentine (to boost the cetane for starting and burning) but I stick with my 70/30 mix to keep it uniform. The Mercedes and The Excursion both prefer the 70/30 mix and get the best performance and economy at that ratio…. ( Read More) – Kevin

——————————————-

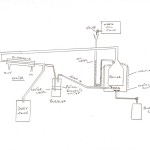

– David

——————————————-

I modified this Becket oil burner to easily burn waste motor oil. It uses an electric heater element from a mini water heater to preheat the WMO. This unit is pictured outside its furnace to show it burning. – Peter

——————————————-

This is a pump I created for fast transfer of WMO. I decided on a gas engine so I can pump oil at any temp, and also not have to rely on elec supply or large air supply at the pickup site. I picked up a broken power washer on craigslist for $40, took off the water pump and fabricated a mounting bracket and drive system, gear reduction pulley set with a jackshaft and automatic belt tensioner. by my timing, it pumps about 30gpm. I can transfer a 275gal tote in 9 min. – Brock

——————————————-

I fill a 250 gal tote tank with waste oil and let it sit for a few weeks to let the water and heavy dirt settle out then i will pump 125 gal from the top of the tank with a wilden pump to a empty tote tank when i have the 125 gal waste oil transferred into that empty tank i will add 30 % (37,5 gal) new diesel so i will have a ratio 70% waste oil and 30 % diesel I mix it before so it will go easier true the Centrifuge specially in the winter it helps. Now i go from this tank to the centrifuge heater and them true the centrifuge I use your centrifuge with the booster inside. on the last pic the booster is not installed i ordered it later and it works much better with the booster, When i get the black diesel out the centrifuge it will run in a empty tote tank and i will add a little injector cleaner and acetone and will mix it. And then the last step i will suck it out of the tank with a Gear pump true a suction 30 micron hydraulic filter true the pump to a 10 micron diesel filter and then true a 5 micron filter in my holding tank I did 2500 gal black diesel before i changed the filters that means the your centrifuge takes out all the dirt, Your centrifuge is working real good for me – Robbie

——————————————-

-Toby

——————————————-

here are a few photo’s of my setup.I use a 60 litre drum in which i put 50 litres of wmo and 7 litres of unleaded petrol,then run it through the centrifugal filter for about 2 hours. It works great in my 1982 Hino AM100 with an EC-100 motor also my 1990 nissan navara with a 2.7 motor.both are the same to start but both are quieter with a little more power.I get a small amount of blueish haze out of the hino but nothing to worry about.I get the oil straight from the serviced cars to my containers so not much contamination. – Steve

Very simple but efficient setup. – Francisco

——————————————-

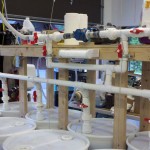

Top tank is for unclean WMO, the middle tank is for unclean wvo, the bottom tank is for a mixture of clean fudged oil to run my furnace. I run usually 50 to 75% in my powerstroke! and in my old fordson diesel tractor. Also in my 1999 new holland diesel skid steer. Non have any modifications. The powerstroke is a 2007 powerstroke 6.0 l. It stays inside a 55deg garage at night. Never gelled in days, even sub zero temps. Wvo is better than WMO in the winter with no heaters or mods, vescosity is thinner. I have since added a homemade heater for the fuge to aid in cleaning. My fuge is a 10″ huge fuge. This spring I will be adding a fuel heater and filter to my truck. And I’m going to buy a vw diesel to convert. I need a new transfer pump.the one pictured melted down. I later attached the pump to an air compressor motor. It runs but loud.not much centering.lol. – Robert

——————————————-

Have been using your RAW centrifuge and motor w/3 ph. converter and pre heater. For over a year now. I have processed well in excess of 3000 gal. of oil. everything from fryer oil to motor and trans. oil. System works great. welded frame and plumbed it up myself. Nice functional set up ! Oil goes into my “Omni waste oil burner” and heats a 5000 sf. metal commercial building. Did some pretty thorough research when looking for centrifuge and related gear. Your equipment came out on top. I will let you know I am still pleased and happy with my decision to go with your equipment to this day ! Thank you ! Appreciate all the info and tech. support on your site as well ! Keep up the Good work!! – Roger

——————————————-

– Carlos

——————————————-

This is it! So simple it hurts. – Rick

——————————————-

I am a huge fan of WMO. I have 2 2000 7.3 trucks as well as a 1997 7.3 motor home as well 3 1987 Merc. 300D’s The two top tanks are for the WMO. The bottom right tank is pump diesel and the lower left tank is the centrifuged oil and that I will add the pump diesel to. I have a DC transfer pump in the cabinet. I cut out the bungs of a 55 gallon plastic container and epoxied them into the corners of the lower tanks to blend the oil and diesel as well as add diesel to the lower right tank. The cabinet also has a male camlock that I will connect to for the purpose of pumping the oil I have gathered to the top two tanks. There are two valves that determine which tank gets the oil. There is also a check valve behind the camlock that keeps the oil from coming back down when I disconnect my pump. – Rick

Notice the sight hose on the end of the tank to see how full the tank is.

Here’s my other 250 gallon oil super sucker loaded and ready to go. Additional 275 gallon tote on board for extra oil containing.

Suction hose and wand.

These are great for collecting oil. The vacuum pumps on top can be reversed for pressurizing the tank for discharging the oil.

Gotta love it! – Ricky

This system uses 100% used motor oil which I have been heating with for the last 2 years. I have had this exact set up since the beginning and it works great for me. My heater can also burn used vegetable oil so this same set up would work as well!

So I find it pretty easy to work with and cleaning the motor oil with the centrifuge makes a big difference; basically the oil coming out of it is just about 100% clean and hardly ever have to clean my filters on the heating unit! – Pierre

I made a larger burner plate, & it really got to goin’–700 deg F on outer shell –about 6″ above burner—but the Alum plate melted & oil ran off edge of plate..

Picked up a 400 gal hi-prss water tank (NEW) surplus @ Ft. Sill fer next to $0–Stood it up on legs & let gravity settle out antifreeze & water – drain out on bottom, another valve in side about 8″ up gets pretty good oil.

See also the 50 gal trk saddle tank that just fits in the trunk of my ’89 Lincoln for collection purposes–that’s an old surplus aircraft hydraulic pump that is used for pickup & transfer–28volt rating, but does just fine on 12V.

I picked up a large HWT that had gone bad @ school, –this one must be 28~30″ in dia–but it is a multi-flue-tube type & I would have to construct a new top & bottom…

Do you know of anyone with success in scaling up the design ? –hate to build another one from scratch, unless I knew it would work..- Jerry

Here are some pics of one of my pumps. I use it to transfer WVO between storage barrels and my BioPro 190 when making biodiesel. I used to hand pump but your pump cut an hour job down to 2 minutes. Thanks! – Kris

——————————————-